Materials Test Lab Insights: Browsing High Quality Evaluations

Wiki Article

Putting Products to the Examination: Discovering the Duty of Products Examination Labs

Materials test labs play an essential function in making certain the top quality and integrity of various materials used in industries such as construction, production, and aerospace. These laboratories carry out extensive testing to assess the performance, strength, resilience, and safety of materials, making it possible for firms to make enlightened decisions regarding their use in items and frameworks. Through a mix of innovative methods and specific equipment, products examination labs are able to analyze the buildings of steels, polymers, composites, and various other products under different conditions and stress factors. The results obtained from these examinations supply important understandings right into material actions, enabling engineers and developers to enhance their products and procedures. This short article will explore the relevance of products screening, the sorts of materials examined, testing methods and devices used, along with the applications of materials examination results. Furthermore, it will go over future trends in products testing, highlighting the continual developments in this area.Significance of Materials Screening

Consistently assessing the high quality of materials is vital in making certain the honesty and safety of products in various industries. This is where materials testing plays a vital role. Materials testing involves subjecting products to numerous examinations and experiments to review their mechanical, physical, and chemical properties. By conducting these distributors, examinations and makers can ensure that their items satisfy the needed standards and requirements.One of the vital reasons materials screening is essential is the assurance of item quality. Via extensive screening, makers can identify any kind of problems or weak points in the materials made use of for their products. This allows them to make required renovations to improve the total high quality and efficiency of their products. Products testing assists in identifying prospective concerns that may arise throughout the item's lifecycle, such as wear and tear, corrosion, or architectural failings. By dealing with these concerns early on, makers can protect against costly recalls, claims, and reputational damages.

Additionally, materials screening is crucial for ensuring the security of products - materials test lab. By subjecting materials to different examinations, suppliers can establish their resistance, strength, and resilience to outside aspects such as warm, pressure, or chemicals. This info is important in developing and producing products that are safe for consumers to make use of. Whether it is auto parts, clinical gadgets, or building materials, materials screening aids in determining any type of prospective safety hazards and creating ideal procedures to alleviate them.

Sorts Of Materials Checked

Various kinds of products are evaluated in products test laboratories to evaluate their mechanical, physical, and chemical buildings. These materials can include a wide variety important, including steels, polymers, porcelains, composites, and also all-natural materials such as wood and concrete.Steels are commonly checked as a result of their widespread use in numerous industries. These tests examine properties such as tensile stamina, firmness, and ductility. Polymers, on the various other hand, are tested to identify their flexibility, thermal security, and resistance to chemicals. Ceramics are examined for their brittleness, resistance, and strength to heats. Compounds, which contain 2 or more different materials, are assessed to comprehend their total efficiency, consisting of variables like stamina, versatility, and toughness.

All-natural materials like timber are tested to assess their toughness, wetness content, and resistance to degeneration (materials test lab). Concrete is one more commonly examined product, with examinations concentrating on its compressive toughness, longevity, and resistance to environmental factors

Along with these materials, products test laboratories also review finishings, paints, adhesives, and various other materials made use of in building, production, and other sectors. By subjecting these materials to strenuous testing, researchers and designers can gather useful data to notify product selection, style optimization, and quality control processes.

Examining Methods and Tools

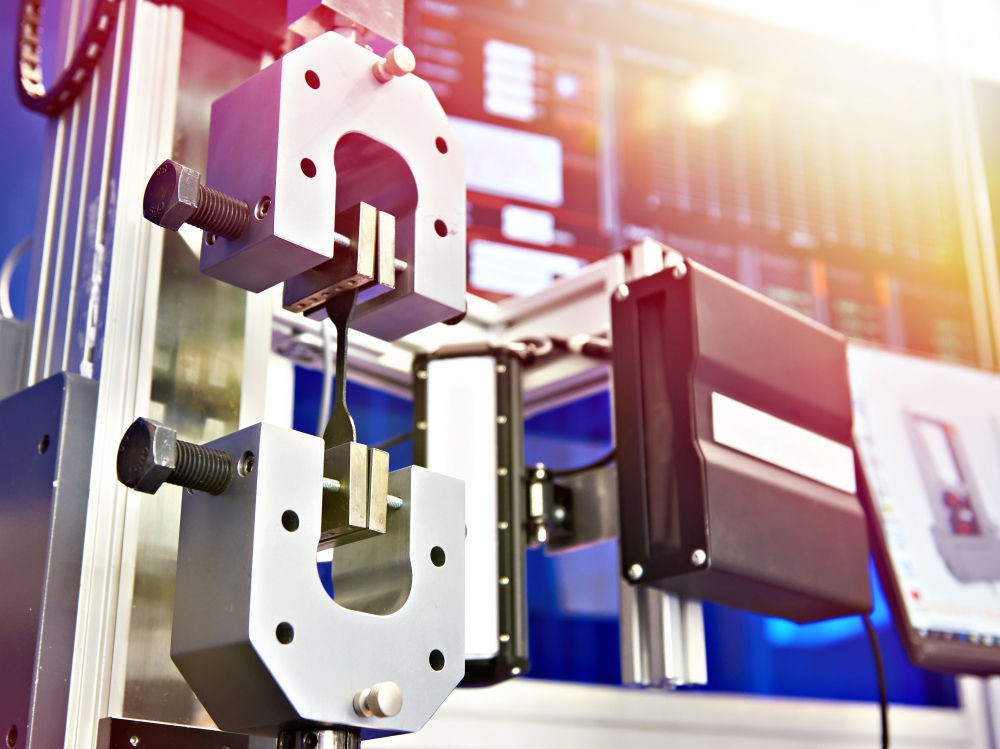

Testing methods and tools play an important duty in materials test laboratories for reviewing the mechanical, physical, and chemical homes of numerous products. These strategies and equipment are necessary in making certain the quality, dependability, and security of products made use of in various industries such as aerospace, vehicle, building and construction, and clinical.One commonly used testing method in materials examination laboratories is mechanical screening, which entails subjecting products to numerous pressures or lots to determine their strength, hardness, ductility, and other mechanical homes. This is commonly done making use of tools such as global screening makers, which can use tensile, compressive, and flexing forces to check specimens.

Physical testing methods are also employed to assess homes such as density, viscosity, thermal conductivity, and electric conductivity. Tools such as thickness meters, viscometers, thermal conductivity analyzers, and electric conductivity meters are utilized to carry out these tests accurately.

Chemical screening strategies are utilized to identify the chemical composition and purity of products. Strategies such as spectroscopy, mass, and chromatography spectrometry are commonly made use of, in addition to specific equipment made for these functions.

Applications of Products Examination Outcomes

The outcomes of materials examining offer valuable understandings right into the efficiency and suitability of various materials for specific applications in various industries - materials test lab. These test results play an important function in identifying the high quality, toughness, and security of materials utilized in manufacturing processesAmong the vital their explanation applications of products test results is in the field of building and construction. Designers and designers rely on these outcomes to choose proper materials for building frameworks, such as bridges, high-rise buildings, and domestic buildings. By performing examinations on materials like steel, timber, and concrete, they can make certain that these materials meet the called for requirements and can withstand numerous environmental conditions.

In the aerospace market, materials examination results are essential in establishing the suitability of products for aircraft parts. By subjecting products to rigorous screening, engineers can examine their mechanical homes, resistance to heat and rust, and ability to stand up to high-stress conditions. This info is crucial in making certain the security and integrity of aircraft.

Future Fads in Materials Screening

In the realm of products testing, improvements in materials checking methodologies are forming the trajectory of the field, ushering in a brand-new era of technology and precision. As innovation continues to progress, so does the demand for more innovative testing methods and tools. One future trend in products screening is the integration of expert system (AI) and device discovering formulas into testing procedures. These technologies have the prospective to improve the performance and accuracy of test outcomes by assessing large amounts of information and recognizing patterns that may not be easily obvious by human beings. Additionally, making use of non-destructive testing methods is coming to be significantly popular. These methods enable for the analysis of product residential or commercial properties without triggering damages or modification to the example, making them excellent for testing irreplaceable or important materials. Additionally, there is an expanding focus on sustainability in materials testing. This includes the development of testing methods that minimize waste and energy consumption, along with using environmentally-friendly products in screening tools. Generally, the future of products testing is defined by continuous development and a commitment to improving performance, sustainability, and precision.Conclusion

In conclusion, materials testing plays a vital duty in numerous industries by ensuring the quality, security, and performance of materials used in products and structures. The results obtained from materials testing are used to make informed decisions in material manufacturing, choice, and style processes.Through a mix of innovative strategies and customized devices, materials test labs are able to assess the properties of metals, polymers, compounds, and various other materials under various problems and stress factors. By carrying out tests on materials like steel, hardwood, and concrete, they can ensure that these products satisfy the required standards and can hold up against different environmental problems.

In the aerospace market, materials examination results are important in determining the viability of materials for airplane elements. By testing products for their resistance, versatility, and toughness to effect, manufacturers can choose the most suitable materials for various vehicle parts, such as body panels, engine parts, and safety and security functions.In the world of materials screening, developments in products testing methods are shaping the trajectory of the field, ushering i was reading this in a brand-new era of advancement and precision.

Report this wiki page